MIL-DTL-29478A(MC)

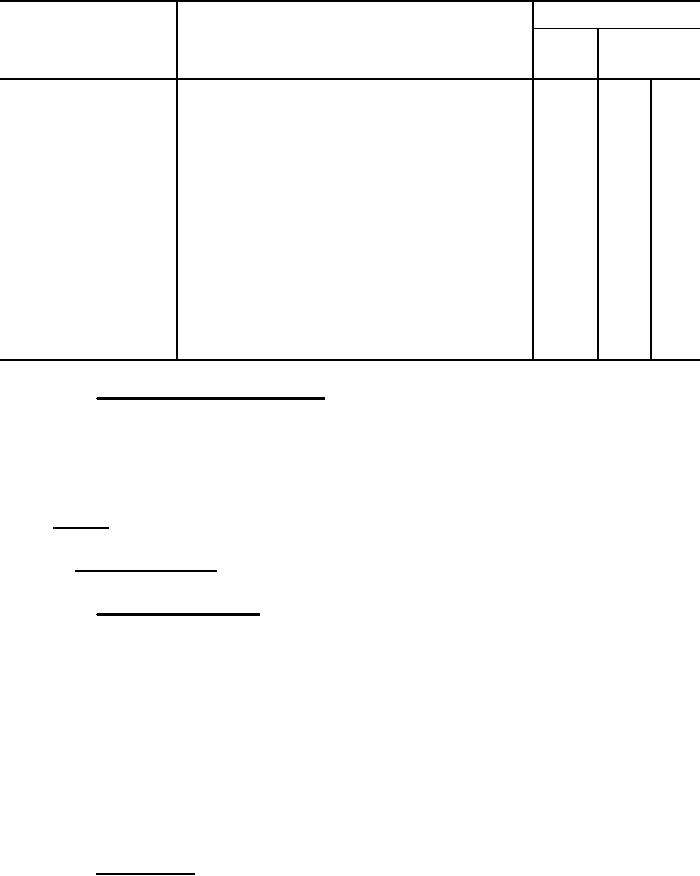

Classification

Examine

Defects

Major

Minor

A

B

c. One or both eyelet covers

231a

not covering eyelet.

d. Width of collar eyelet cover

369

less than 1-5/8 inches or more

than 1-7/8 inches.

e. Felling on front edge and

232a

along lower corner of one or

both eyelet covers omitted.

f. Felling along lower corner

370

of one or both eyelet covers

extending for a distance of

more than 3/4 inch.

4.4.3.4. Finished measurements. Any measurements deviating from

the nominal dimensions and tolerance specified in Table II shall

be classified as a size measurement defect. Sleeve lengths

uneven by 1/2 inch or more shall be classified as size

measurement defect.

4.5. Tests.

4.5.1

Lacquer tests.

4.5.1.1. Liver of sulfur. The samples to be tested shall be

immersed in a two percent by weight chemically pure liver of

sulfur (potassium sulphide) water solution, at a temperature of

100°F, for not less than three minutes. The samples shall then

be removed and rinsed in warm, then cold, then hot water, after

which they shall be wiped gently in an absorbent cellulose

material or whirled to remove residual moisture, and allowed to

air dry at room temperature for a period of one hour. There

shall be no change in the appearance of the lacquered surfaces

except for a slight overall yellowing and not more than three

dark spots, each not exceeding 1/32 inch largest dimension.

4.5.1.2. Tackiness. At room temperature (60° to 80°F) press a

piece of tissue paper against the lacquered surface for 30

seconds, using any pressure capable of being exerted by the thumb

and two fingers. The tissue shall not adhere to the lacquered

surface, but shall fall free when pressure is released.

72

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business