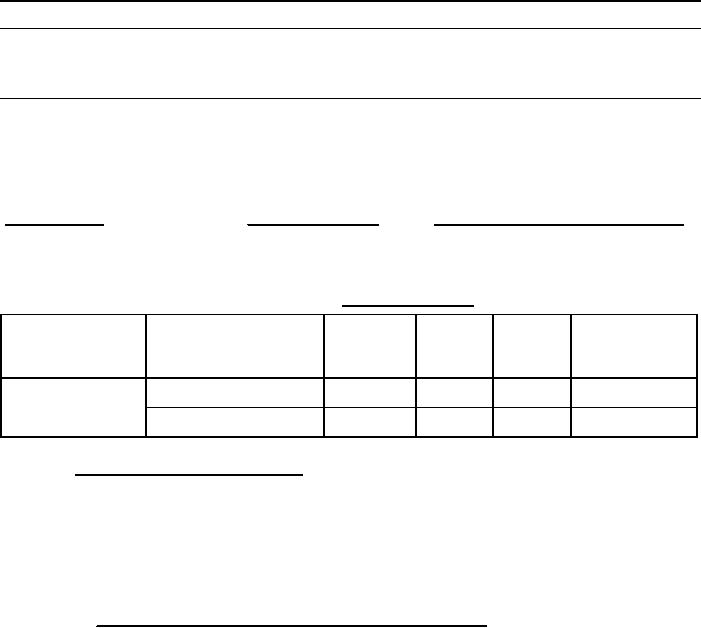

MIL-DTL-29396B(MC)

Lot size

Sample size

800 or less

2

801 to 22,000 inclusive

3

22,001 and over

5

The unit for expressing lot sizes and sample unit for testing

each component shall be in accordance with applicable subsidiary

specifications as follows:

Component

Expressed as

Sample unit for testing

Hook and eye

100 each

two each, hook and eye

TABLE III.

Test methods.

No. det.

Reqmt.

Test

per

Results

Components

Characteristics

para.

method

S/Unit

reported as

Hook and eye

Liver of sulphur

3.3.15

4.5.1.1

1

Pass or fail

Tackiness

3.3.15

4.5.1.2

1

Pass or fail

4.4.2 In-process inspection. Inspection shall be performed

during the manufacturing of the end item to ascertain that the

operations are performed as specified herein. The Government

reserves the right to determine the acceptability of construction

methods not performed in accordance with specified requirements

for operations or subassemblies.

4.4.2.1. Bond strength of fusible interlining. The strength of

the bond of the fusible interlining to the outer shell shall be

tested once each four hours as follows. At each fusing press to

determine that adequate fusing is being obtained. Prepare a test

sample by fusing the fusible interlining specified in 3.3.6 to

the basic fabric of the outer shell specified in 3.3.1 under the

same fusing conditions to be used in the manufacture of the

jacket. Determine the bond strength of the test sample with a

commercial spring scale (see 6.6). If the bond strength of any

test sample is less than 22 ounces per inch of width, the fusing

conditions shall be corrected and the bond strength test shall be

repeated. Those units represented by this test shall be fused

again and retested. If they fail, they shall be rejected.

45

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business