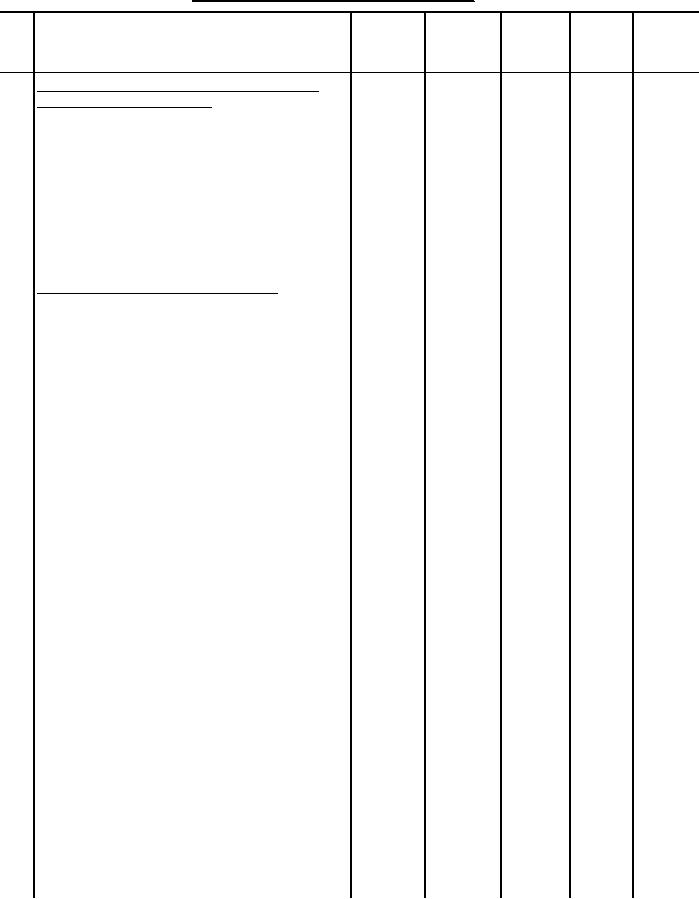

MIL-DTL-29396B(MC)

Manufacturing requirements - Continued.

TABLE I.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

60 Fell back lining and facing-lining

assembly at shoulders.

a. Fell the back lining and facing-

lining assembly together at the

shoulders, placing the stitching over

the folded edge of back lining and

securing the top end of the chest

pleat and the eyelet cover in the

felling. Fell the eyelet cover along

the facing-lining seam line from the

bottom edge up to the shoulder line.

61 Fell sleeve lining at armhole.

a. Position the sleeve lining at the

armhole with the back and forearm

seams of the sleeve and sleeve lining

matching.

b. Turn under the armhole edge of

Hand

8-10

C

the sleeve lining and lap the lining

(silk)

on the outside of the front and back

lining and the top edge of the

underarm shield. Fell the sleeve

lining to the jacket around the

entire armhole, placing the stitching

over the folded edge of the sleeve

lining, catching the underarm shield

in the felling and distributing the

fullness in accordance with good

commercial practice. Backstitch the

lower armhole edge from backarm seam

of sleeve to the front edge of the

shield.

c. Machine stitch the lower edge of

301

SSa-1

10-14

A

A

the sleeve lining, at the armhole, on

the inside from forearm seam to

backarm seam and hand fell the

remaining portion as specified in

operation 60.a.

-or-

d. Machine stitch the lower edge of

Machine

8-10

C

the sleeve lining, at the armhole on

(silk)

the inside from forearm seam to

backarm seam and stitch the remaining

portion of the sleeve lining at the

armhole with machine simulated hand

felling.

37

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business