MIL-DTL-29478A(MC)

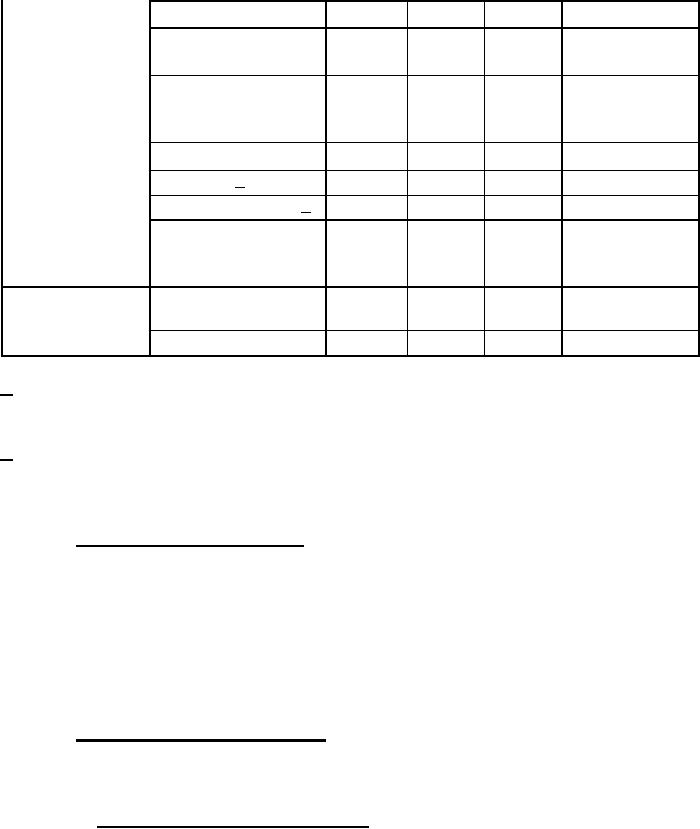

Ornamental braid

Weave

3.3.15

Visual

1

Pass or fail

Weight, oz. per

3.3.15

5041

1

To nearest

gross yards

3.3.15

4.5.2

0.1 oz.

Texture (picks and

3.3.15

Visual

5

Avg. of five

ends)

det. to nearest

whole no.

No. of carriers

3.3.15

Visual

1

To nearest no.

Shrinkage 1/

3.3.15

5558

Breaking strength 2/

3.3.15

5100

Colorfastness to:

3.3.15

5622

-wet (dry) cleaning

3.3.15

5660

-light

Hook and eye

Material

3.3.17

Std

1

Pass or fail

identification

com'l

Finish

3.3.17

4.5.1

1

Pass or fail

1/

Except that the width of the test specimen shall be the full

width of the braid.

2/

Breaking strength shall be determined on the full width of

the braid and the jaw dimensions shall be greater than the

width of the braid.

4.4.2 In-process inspection. Inspection shall be performed

during the manufacturing of the end item to ascertain that the

operations are performed as specified herein. The Government

reserves the right to determine the acceptability of construction

methods not performed in accordance with specified requirements

for operations or subassemblies. When specified in the contract

or purchase order a production/acceptance inspection procedures

and production inspection reports shall be prepared.

4.4.3 Examination of end item. The end item shall be examined

for defects listed in 4.4.3.2 through 4.4.3.3. The sample unit

shall be one coat.

4.4.3.1. Classification of defects. All defects shall be

classified as indicated below, except those numbered 1 and 2 in

the major classification column which shall be classified as

follows:

Major defect

- When seriously affecting appearance or

serviceability.

50

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business