MIL-DTL-29478A(MC)

Manufacturing requirements - Continued.

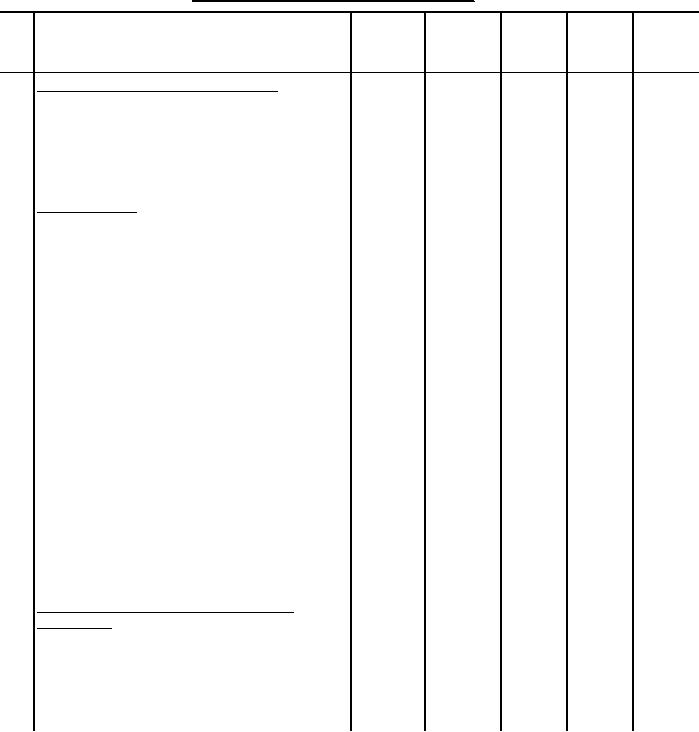

TABLE I.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

69 Fell sleeve lining at armhole.

(cont'd)

NOTE: It is required that the

simulated hand felling produced by

machine shall be equal to or better

than the hand felling.

70 Fell facings.

a. Fell the facing to the piping at

Hand

8-10

C

the bottom edge of the coat, starting

(silk)

at the bottom edge of the lining and

continuing along the back and bottom

edges of facing to the front edge of

coat.

b. Fell the folded edge of the

Hand

8-10

C

facings to the piping along the top

(silk)

edge from collar to notch to front

edge of coat.

c. Fell the eyelet cover to the

Hand

8-10

C

right front facing along the bottom

(silk)

edge of cover.

d. Tack the eyelet cover to the

Hand

4-6 per

C

right front facing along the folded

tack

(silk)

edge of lining. Place one tack

midway between the second and third

eyelet from the top, and one tack

midway between the fourth and fifth

eyelet from the top.

71 Sew hook and eye to collar (see

Figure 7).

Finished appearance. The hook and

eye shall be positioned to properly

engage each other, effecting a flat,

smooth closure at the front of the

collar without misalignment.

44

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business