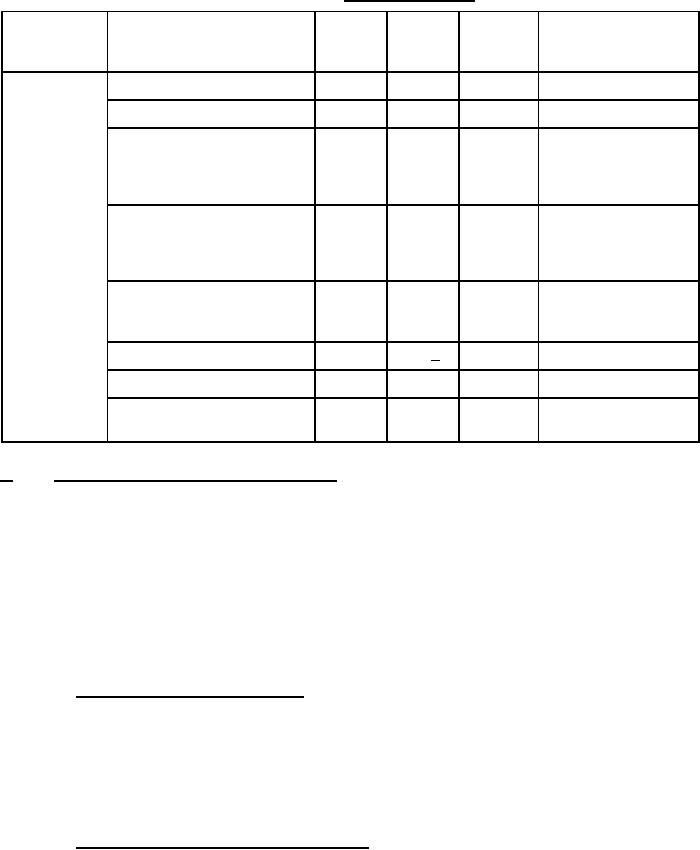

MIL-DTL-29479A(MC)

TABLE III.

Test methods.

No. det.

Reqmt.

Test

per

Results reported

Components

Characteristics

para.

method

S/unit

as

Lining

Material identification

3.3.3

1530

1

Pass or fail

Weight-oz/sq. yd.

3.3.3

5041

5

Pass or fail

Breaking strength - lbs:

Average of the

- warp

3.3.3

5100

5

five det. in each

- filling

direction to the

nearest 1.0 lb.

Tearing strength - lbs:

Average of the

- warp

3.3.3

5134

5

five det. in each

- filling

direction to the

nearest 1.0 lb.

Yarns per inch (min.)

Average of the

- warp

3.3.3

5050

5

five det. in each

- filling

direction

Shrinkage

3.3.3

See 1/

1

Pass or fail

Weave

3.3.3

Visual

1

Pass or fail

Acidity (pH)

3.3.3

2811

5

Average of the

five det.

1/

Determination of shrinkage. Shrinkage shall be determined

in accordance with Method 5558 except that the specimen

shall be 22 inches by 22 inches without slits, soaked for

one hour, and if an extractor is not available, the excess

water shall be removed by wrapping the specimen in a towel

or similar material and squeezed by hand. Wringing by hand

or passing the specimen between squeeze rollers is

prohibited. The extracted specimen shall be dried by

pressing at a temperature not to exceed 275°.

4.4.2 In-process inspection. Inspection shall be performed

during the manufacturing of the end item to ascertain that the

operations are performed as specified herein. The Government

reserves the right to determine the acceptability of construction

methods not performed in accordance with specified requirements

for operations or subassemblies.

4.4.3 Examination of the end item. Samplings and examination of

the end item shall be performed for dress (D) slacks in

accordance with the provisions of MIL-STD-656.

24

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business