MIL-DTL-29479A(MC)

Manufacturing requirements - Continued.

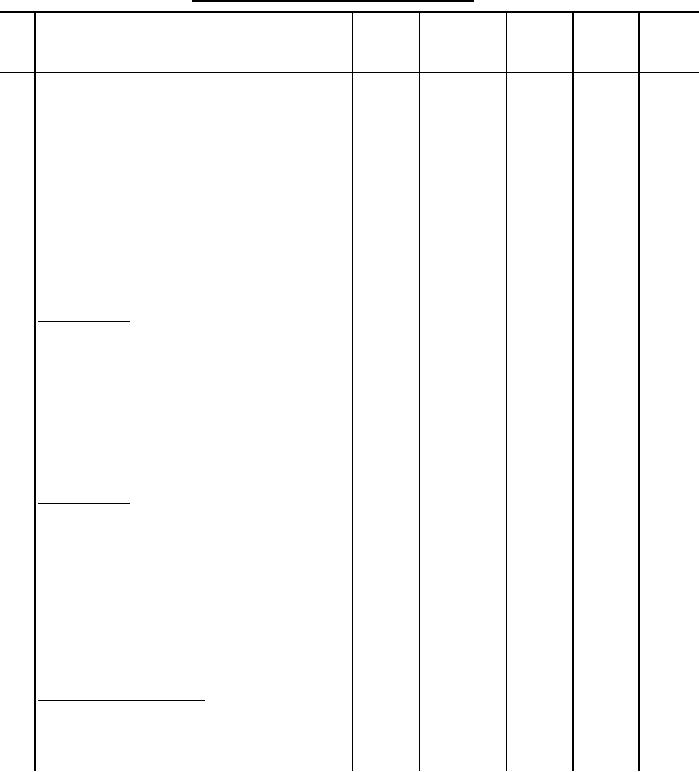

TABLE I.

SEAM/

STCH

STCH TYPE

BOB/

NO

OPERATION

TYPE

STCH/IN

NDL

LPR

c. Spread open crotch and seat seams

and press smooth and flat with a

heated pressing machine tucking in

the stitching tail under the pressed

open seat seam.

d. The inseam at the crotch shall

not stagger more than 1/4 inch.

e. Topstitch through the finished

301

LSq-1

8-10

A

A

waistband superimposing the

topstitching and catching the pressed

open seat seam at the top of the

waistband.

23 Bartack fly.

Finished appearance. The bartacks

shall be properly positioned and

correctly placed to reinforce the

points of strain.

a. Bartack the bottom end of the fly Bartack

21-28

0

0

horizontally through all plies at the

per

juncture of the crotch seam and fly

bartack

(see Figure 2).

23 Bartack fly.

(cont'd)

b. Bartack the inside front edge of Bartack

21-28

0

0

right fly to back of left fly with a

per

horizontal bartack. Bartack shall be

bartack

1 ± 1/4 inch from bottom folded point

of right fly.

c. Bartacks shall be 3/8 to 1/2 inch

long and shall be stitched through

all plies of material at the point of

bartacking.

24 Finish slack bottoms.

a. Overedge stitch or pink the slack

503

EFd-1

8-10

70/2

70/2

bottoms.

or

504

19

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business