MIL-DTL-29397B(MC)

Manufacturing requirements - Continued.

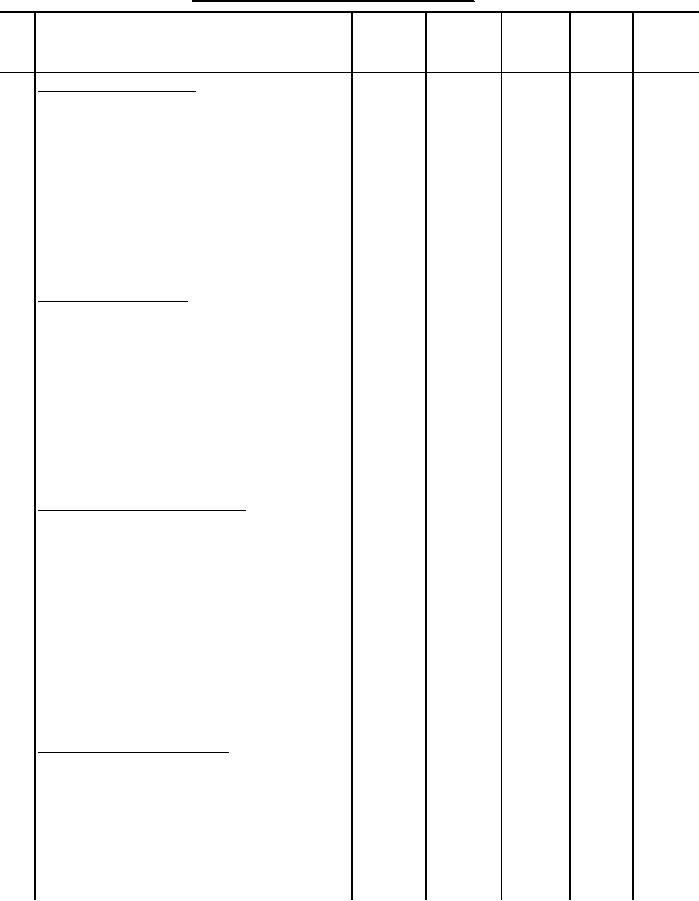

TABLE I.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

Make shoulder loops.

4

(cont'd)

a. Fold the strap for the loops in

301

SSa-1

10-14

A

A

half lengthwise and seam together 1/4

inch from raw edges.

b. Press the seam open, smooth and

flat with a heated pressing iron.

c. Turn strap right side out, with

seam line placed in center on the

underside and press smooth and flat

with a heated pressing iron.

5

Make jacket hanger.

Finished appearance. The jacket

hanger shall finish 1/4 to 3/8 inch

wide.

a. Fold the 1-1/8 inch wide strip of

301

EFp-1

10-14

A

A

lining material in half lengthwise.

Turn the edges to the inside and seam

1/16 inch from the turned edges.

b. Cut the jacket hanger 3-3/4 ± 1/4

inches long.

6

Make collar eyelet covers.

Finished appearance. The collar

eyelet covers shall finish 1-3/4 ±

1/8 inches wide.

a. Turn under the side edges of the

301

EFa-1

10-14

A

A

collar eyelet covers and stitch 1/8

(each

inch from the folded edges, catching

side

the turned under portions in the

edge)

stitching.

b. Fold each cover in half across

301

SSa-1

10-14

A

A

the width and seam 1/16 inch from the

folded side edges.

Make front eyelet cover.

7

a. Fold front eyelet cover in half

301

SSa-1

10-14

A

A

lengthwise and stitch across the

bottom edge with a 1/4 inch seam.

b. Turn the cover right side out.

Press and crease the folded edge

smooth and flat with a heated

pressing iron.

13

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business