MIL-DTL-29397B(MC)

Manufacturing requirements - Continued.

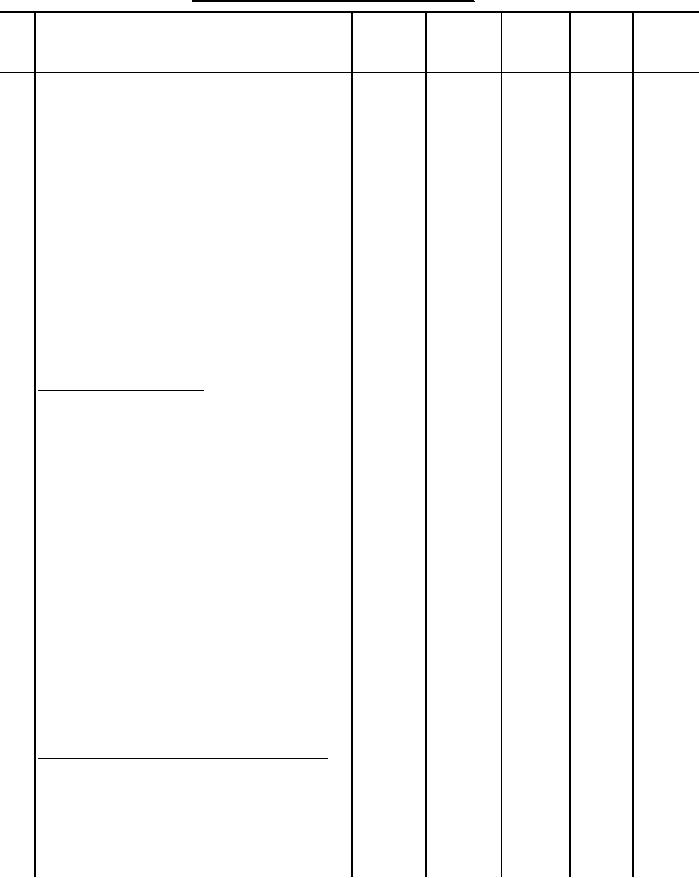

TABLE I.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

b. Fold the front lining lengthwise

301

OSf-1

10-14

A

A

with notches matching, and stitch

front darts in accordance with marks

as indicated on the patterns. The

line of stitching for the darts shall

be 3/8 inch from the folded edge of

the dart at the bottom tapering to a

flat point at the top end, and

securely backtacked.

c. Position the center back lining

301

SSa-1

10-14

A

A

with back edges even and notches

matching. Seam together from the

upper notches for a distance of

approximately 2 inches, and from that

point seam horizontally to 3/8 inch

from the back edge, and continue

seaming to the bottom end of lining.

22 Assemble body lining.

(cont'd)

d. Position the center back to the

301

SSa-1

10-14

A

A

respective side backs with edges even

and notches matching. Join together

with 3/8 inch seam.

e. Position side back and side front

301

SSa-1

10-14

A

A

face to face with edges even and join

together at the side with 3/4 inch

seam.

f. Press the darts and side seams of

lining smooth and flat with a heated

pressing iron toward the back, and

press the left and right side back

lining seam toward center back.

g. Press the pleat at center back

smooth and flat from top to bottom

edge. The folded edge of pleat on

the outside of lining shall be toward

the right side as worn.

23 Attach front eyelet cover to facing.

a. Position the eyelet cover on the

301

SSa-1

10-14

A

A

outside of the right front facing,

with the top, bottom and front raw

edges even. Stitch the cover to the

facing 3/16 to 1/4 inch from raw

edges.

22

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business