MIL-DTL-29397B(MC)

Manufacturing requirements - Continued.

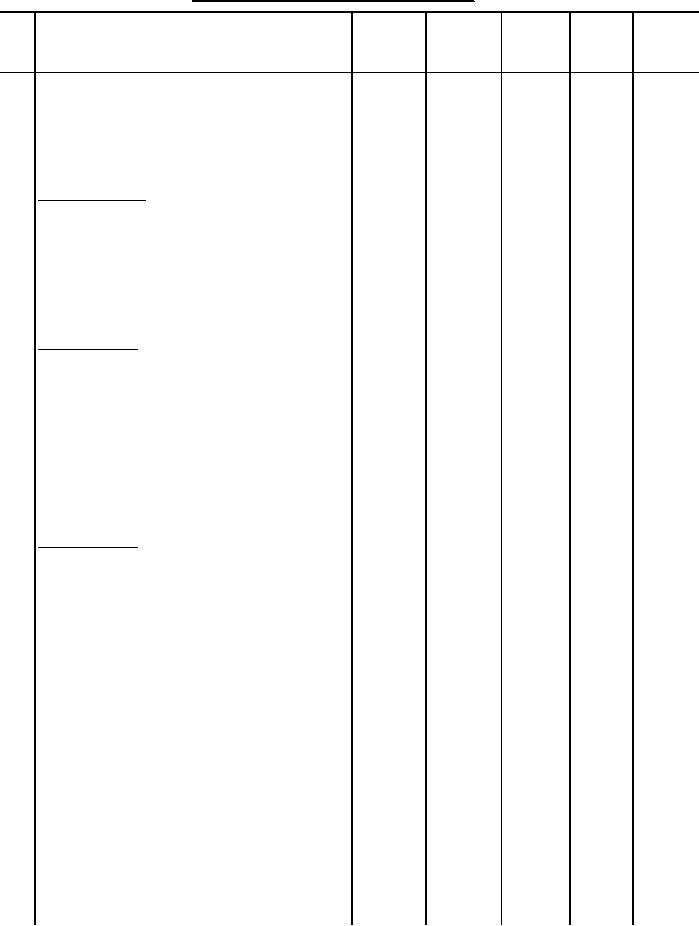

TABLE I.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

c. Turn under and fell the lower

Hand

8-10

C

edge of the collar lining to the

(silk)

jacket from end to end, catching the

turned under portion of the lining at

the right and left end in the

felling.

71 Finish collar.

(cont'd)

d. The lower edge of the collar

Hand

8-10

C

lining may be basted to jacket prior

(silk)

to felling.

e. Turn back collar lining extension

tab and hand fell directly behind

eyes.

72 Clean jacket.

a. Pull all basting thread, trim and

remove any loose ends of thread, and

remove any spots, stains and tickets

without injury to the material.

b. Buttonholes at front closure

shall be examined for exposure of

jacket front interlining cloth. The

exposed interlining shall be colored

with a reddish indelible ink.

73 Press jacket.

a. The jacket shall be well pressed

throughout with a heated pressing

iron or pressing machine of a type

suitable to obtain the desired shape

and appearance in accordance with

good manufacturing practices.

b. Press the fronts smooth and flat,

straightening and shaping the front

edges and working the fullness

towards the chest. Care shall be

exercised in pressing the fronts so

that the bottom edges are even.

c. Press the entire collar smooth

and flat.

d. Press the front on a body

machine, shrinking and properly

shaping the chest.

e. Press the sides, working the

fullness towards the back.

44

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business