MIL-DTL-29397B(MC)

Manufacturing requirements - Continued.

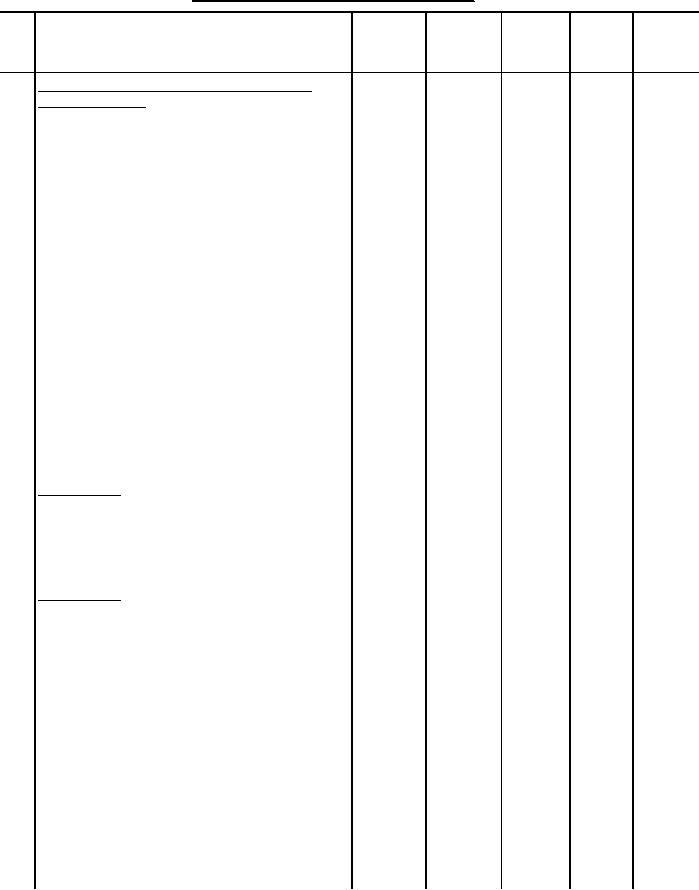

TABLE I.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

61 Seam neckline with size label and

jacket hanger.

Finished appearance. The neckline

shall finish smooth and flat, without

twists, pleats or puckers. The size

label shall be positioned between the

ends of the jacket hanger and the

ends of the jacket hanger shall be

positioned so that in the finished

jacket, the hanger opening shall be 2

± 1/8 inches long when measured along

the lower edge of collar lining.

a. Join facings and back lining to

301

SSa-1

10-14

A

A

jacket at the neckline from collar

notch to collar notch, with a 1/4

inch seam and with the upper edge of

the size label and the ends of the

hanger positioned and caught in the

stitching at the inside center back.

b. Press the neckline of the jacket

smooth and flat with a heated

pressing iron or pressing machine.

62 Set collar.

Finished appearance. The collar

shall be carefully joined to the

jacket without distortion of the

collar.

62 Set collar.

(cont'd)

a. Mark the neckline on the outside

3/8 to 1/2 inch from collar notch up

to the shoulder seam and gradually to

within 1 to 1-1/4 inches at the

center back for position of collar.

b. Position the collar with the

lower edge lapped on the outside top

edges of the jacket at the mark.

c. Stitch the collar from end to

301

LSa-1

10-14

A

A

end, to the jacket, as close as

(silk)

possible to, but not on top of, the

stitching for the piping at the lower

edge of the collar. The stitching

shall not be through the collar

lining.

39

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business