MIL-DTL-29397B(MC)

Manufacturing requirements - Continued.

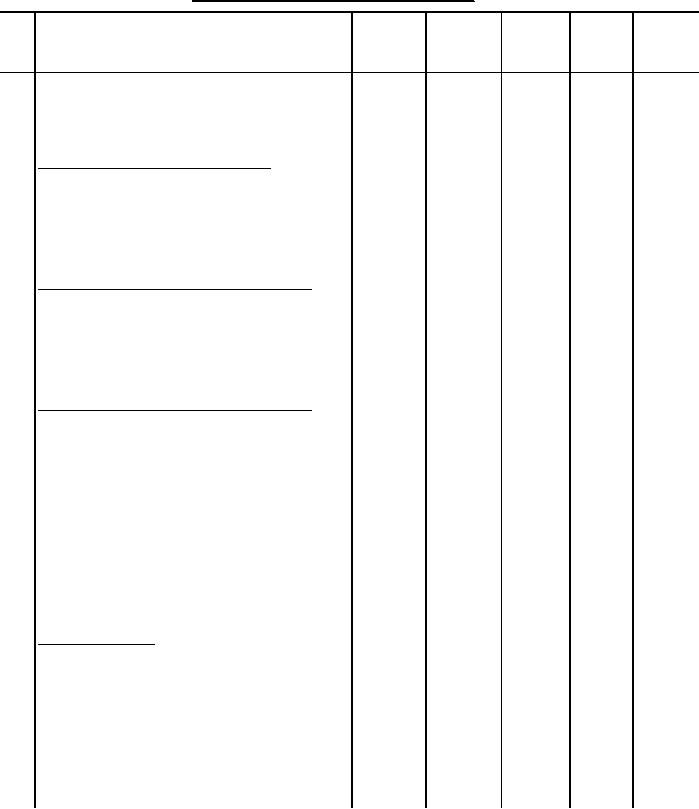

TABLE I.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

a. Press the front of jacket and

braid smooth and flat with a suitable

pressing machine, removing the

fullness.

55 Baste shoulder pad to jacket.

a. Insert shoulder pads between

Hand

interlining and chest padding of

or

301

Hopper

jacket fronts. Securely tack the pad

to the interlining and chest padding

only.

56 Set shoulder loops (see Figure 5).

Finished appearance. The shoulder

301

SSa-1

10-14

A

A

loops shall be securely stitched

without causing distortion to the

shoulder. The loops shall finish 5/8

inch wide and 1 inch long.

56 Set shoulder loops (see Figure 5).

(cont'd)

a. Position the raw edge of one loop

on the front of the jacket at the

shoulder edge, 1-1/4 inches from the

raw edge of neck gorge and stitch

loop to jacket 1/8 inch from raw

edges. The outside edge of the

second loop shall be positioned 3-3/4

inches from the outside edge of the

first loop and at the shoulder edge.

Stitch loop to jacket 1/8 inch from

the raw edge.

57 Seam shoulders.

Finished appearance. The shoulder

seam shall finish without a distorted

appearance.

a. Join the back to the front at the

301

SSa-1

10-14

A

A

shoulders with a 3/8 inch seam,

working in the fullness on the back

in accordance with good manufacturing

practice.

37

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business