MIL-DTL-29395B(MC)

Manufacturing requirements - Continued.

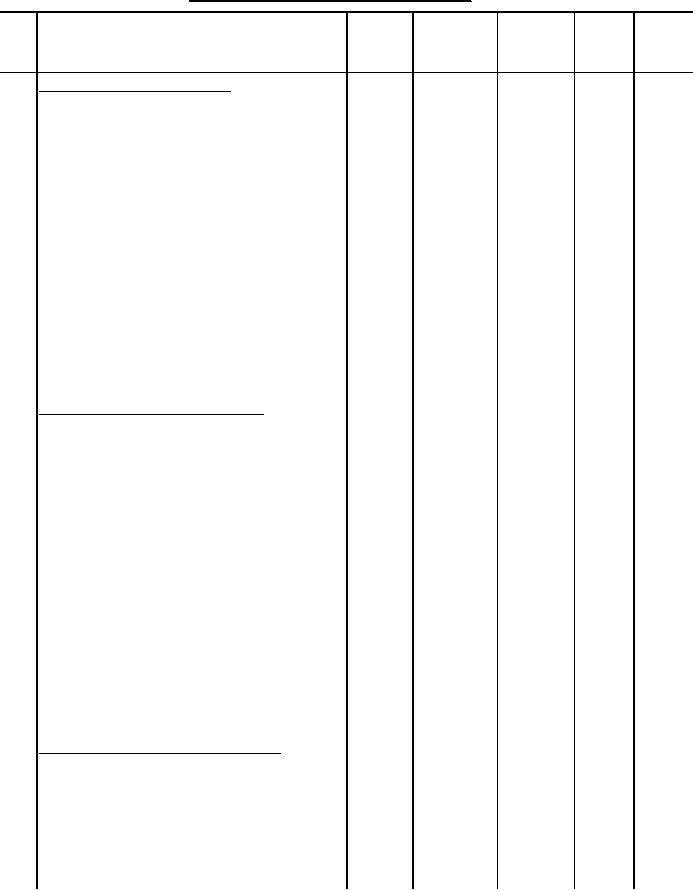

TABLE I.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

4

(cont'd)

Make ornamental stripes.

b. Fold the raw edges of the scarlet

101

4-6

stripes to the center back, abutting

the raw edges. Baste along the

folded edges.

c. Fold the white stripe in half

301

OSf-1

10-14

A

A

lengthwise and stitch together 1/8

inch from the folded edge forming a

corded edge.

d. Position the two scarlet stripes

301

SSav-4

10-14

A

A

on each side of the corded white

stripe with one folded edge of each

scarlet stripe abutted against the

corded edge. Stitch each inner edge

of the scarlet stripe to the white

stripe 1/16 inch from the folded

edge.

5

Make darts (basic material).

The darts shall be tapered on the

inside without twists or puckers.

Thread ends at lower end of darts

shall not be trimmed closer than 1/2

inch in length. End of dart need not

be backtacked except when automatic

dart machine is used.

a. Fold and stitch back darts as

301

OSf-1

12-14

50/3

50/3

indicated by notches and marks on the

pattern. Press toward center back.

Stitch across top of dart 1/8 inch

from raw edge.

b. Fold and stitch front darts as

301

OSf-1

12-14

50/3

50/3

indicated by notches and marks on the

pattern. Press toward the center

front. Stitch across the top of dart

1/8 inch from raw edge.

6

Make darts (lining - class 3).

a. The darts shall be tapered on the

inside without twists or puckers.

Thread ends at lower end of darts

shall not be trimmed closer than 1/2

inch in length. End of dart need not

be backtacked except when automatic

dart machine is used.

11

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business