MIL-DTL-29395B(MC)

Manufacturing requirements - Continued.

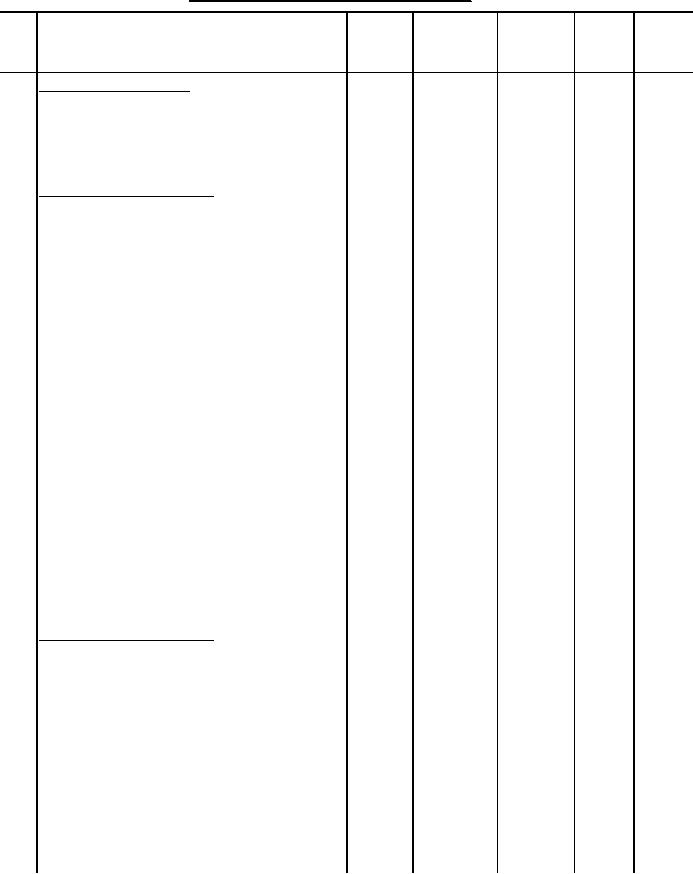

TABLE I.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

Overedge stitching.

9

(cont'd)

d. Position the interlining on the

503

EFd-1

8-10

70/2

70/2

left fly facing and overedge stitch

or

the back edge of interlining and

504

facing together.

10 Set hip pocket bearer.

Finished appearance. The back pocket

bearer and facing shall be properly

positioned and securely sewn with the

stitching of uniform gage and without

pleats, puckers or other distortions.

a. The back pocket bearers shall

each be a single ply of basic

material.

b. Position the bearer on the pocket

material in accordance with notches

indicated by marks on the pattern.

c. Fold under the lower raw edge of

301

LSd-1

10-14

50/3

50/3

bearer and facing 1/4 to 3/8 inch and

and

stitch to the pocket 1/8 inch from

LSbj-1

the folded edge. Continue stitching

across the bottom raw edge. A

selvage edge need not be turned.

d. Position the label on the folded

301

SSa-1

10-14

50/3

50/3

edge of right pocket, facing the

wearer, and stitch the label to the

pocket 1/16 to 1/8 inch from the

label edge.

11 Make hip pocket flaps.

Finished appearance. The hip pocket

flaps shall finish smooth and flat,

without twists, pleats, or puckers,

and shall be uniform in shape and

size in accordance with patterns.

The lining shall not be exposed on

the outside. The edges of the flaps

shall be well forced out and the edge

stitching shall be uniform in width.

The buttonholes shall be correctly

positioned, clean cut, and well made,

and the stitching securely caught in

the basic material.

13

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business