MIL-DTL-29395B(MC)

Manufacturing requirements - Continued.

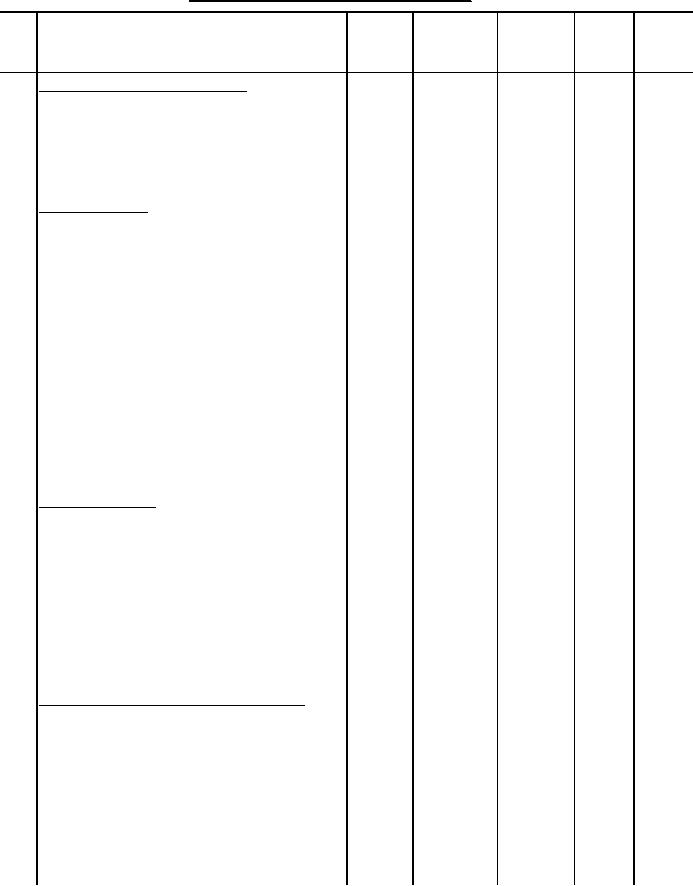

TABLE I.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

17 Join crotch and seat seam.

(cont'd)

e. Topstitch through the finished

301

LSq-1

8-10

A

A

waistband superimposing the

topstitching and catching the pressed

open seat seam at the top of the

waistband.

18 Make left fly.

Finished appearance. The left fly

shall finish smooth and flat without

twists, puckering or distortion.

The overedge stitching shall be

securely caught in the fabric.

a. Position the slide fastener on

301

LSbj-2

12-14

50/3

50/3

the left fly facing and left fly

interlining with bottom end of chain

1/4 inch above the fly notch and top

edges even. The front edge of chain

shall be 1/2 to 5/8 inch from front

edge of finished fly. Stitch slide

fastener tape to the fly through the

interlining with a double row of

stitches 3/16 to 1/4 inch gage.

19 Make right fly.

Finished appearance. The right fly

shall finish without bulkiness,

twists, puckers or pleats.

a. Position the slide fastener on

301

LSbj-2

12-14

50/3

50/3

the fly with the slide fastener tape

1/2 inch from the overedged seam and

the top edges even. Stitch the slide

fastener to the fly 1/2 inch from the

back edge of fly.

20 Join left and right fly to front.

Finished appearance. The seam

joining the fly assemblies to the

front shall be without pleats,

puckers, twists or other distortions.

a. Position the left fly assembly on

301

SSa-1

12-14

50/3

50/3

the outside of left front, face to

face, with notches matching. Join

left fly assembly to front with a 1/2

inch seam.

20

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business