MIL-DTL-29397B(MC)

Manufacturing requirements - Continued.

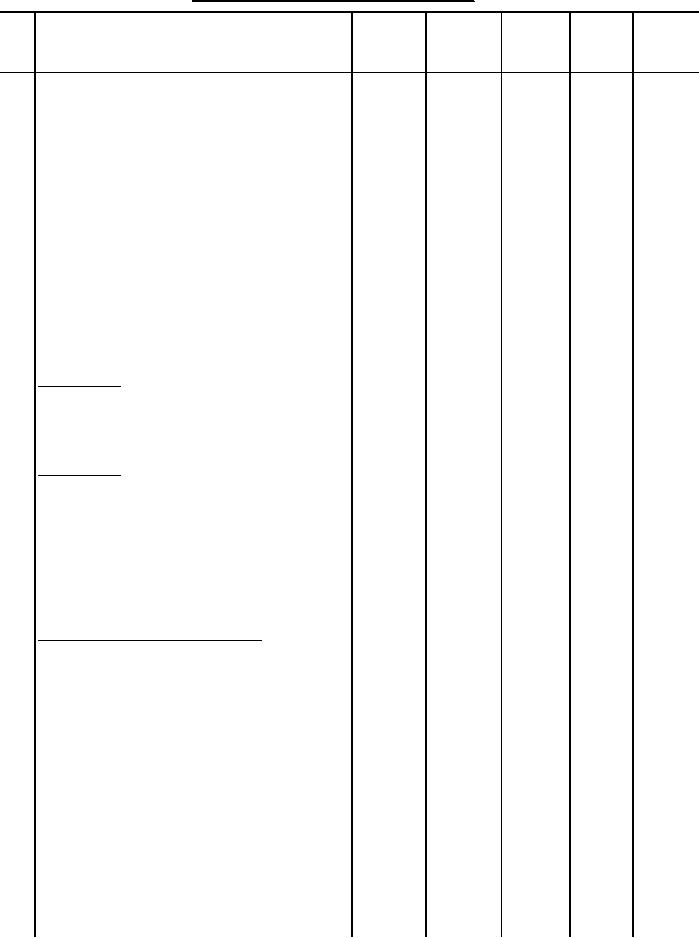

TABLE I.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

b. Begin with cut end of braid even

Hand

2-6

C

(silk

with straight line at top of harp.

Baste the braid along its forward

black)

edge down the center of harp to the

forward edge of harp center.

Continue up the backarm along the

back edge of harp to the straight

line at top using the same edge of

the braid.

c. Baste the bottom edge of braid

Hand

2-6

C

along the straight line to the

(silk

circle, follow circle back to

black)

straight line and continue to end of

straight line.

d. Repeat steps a, b, and c on each

marking on fronts.

36 Tack braid.

a. Securely tack all unattached

Hand

2-6

C

edges of braid to provide a smooth

(silk

secure and flat surface of stitching.

black)

36 Tack braid.

(cont'd)

b. Tack inside edges of braid

Hand

2-6

C

circles to jacket, forming an inner

(silk

hole approximately 1/8 inch in

black)

diameter.

c. Tack loops at button edge of

Hand

2-6

C

jacket to finish secure and flat.

(silk

black)

37 Stitch braid (see Figure 4).

Finished appearance. All stitching

shall be done 1/16 inch from all

edges whenever possible. All

stitching shall be uniform. All

stitching shall be performed with one

continuous thread whenever possible.

Stitching across braid strands shall

be done only as described or when

absolutely necessary. All edges of

the braid shall be securely attached

to the jacket at all points. The

braid and the stitching shall present

a smooth, neat, uniform appearance.

The braid on the left front only

shall be unstitched for approximately

3 inches from front end of the

buttonhole loop braid.

29

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business