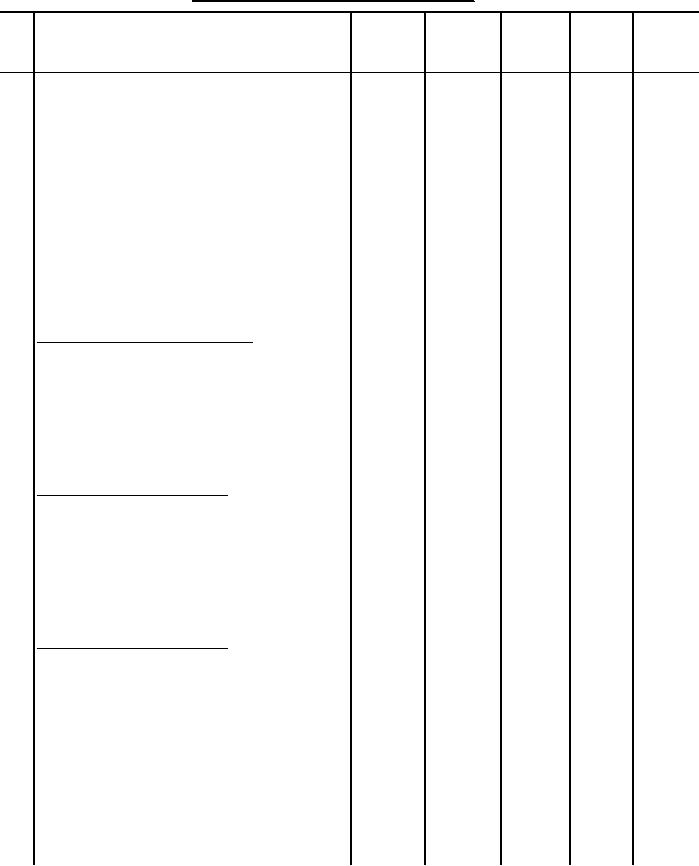

MIL-DTL-29396B(MC)

Manufacturing requirements - Continued.

TABLE I.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

Hand

c. Baste the facing to the fronts as

close as possible to the facing-

or

Hopper

lining seam, placing the fullness

301

over the chest and distributing the

fullness in the facing in accordance

with good commercial practice. The

basting shall extend from

approximately 3 inches from shoulder

edge of facings to approximately

1-1/4 inches from the lower edge of

facing.

d. Turn under the bottom edge of

Hand

facing at the mark and baste along

or

the folded edge.

301

Hopper

42 Tack facing to interlining.

a. Tack the right and left facing-

Hand

4-6

lining seam allowance to the

or

respective jacket front interlining

301

SSm-1

4-6

from approximately 2 inches from

bottom edge of jacket to

approximately 3 inches from the

shoulder edge.

43 Baste linings to jacket.

a. Fold the front lining in

Hand

accordance with the notches forming

or

the chest pleat, and baste along the

301

Hopper

entire center of the pleat. The

folded edge of the pleat on the

outside of the lining shall be

towards the armhole.

43 Baste linings to jacket.

(cont'd)

b. Baste the front lining to the

Hand

jacket, starting at the lower end of

or

the chest pleat, continuing along

301

Hopper

lower edge of armhole approximately 2

inches from the edge and ending at

the side seam. Match side seams of

jacket and lining and continue

basting as close as possible to the

side seam and then across the bottom

towards the front approximately 4

inches from piped bottom edge of

jacket.

30

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business