MIL-DTL-29396B(MC)

Manufacturing requirements - Continued.

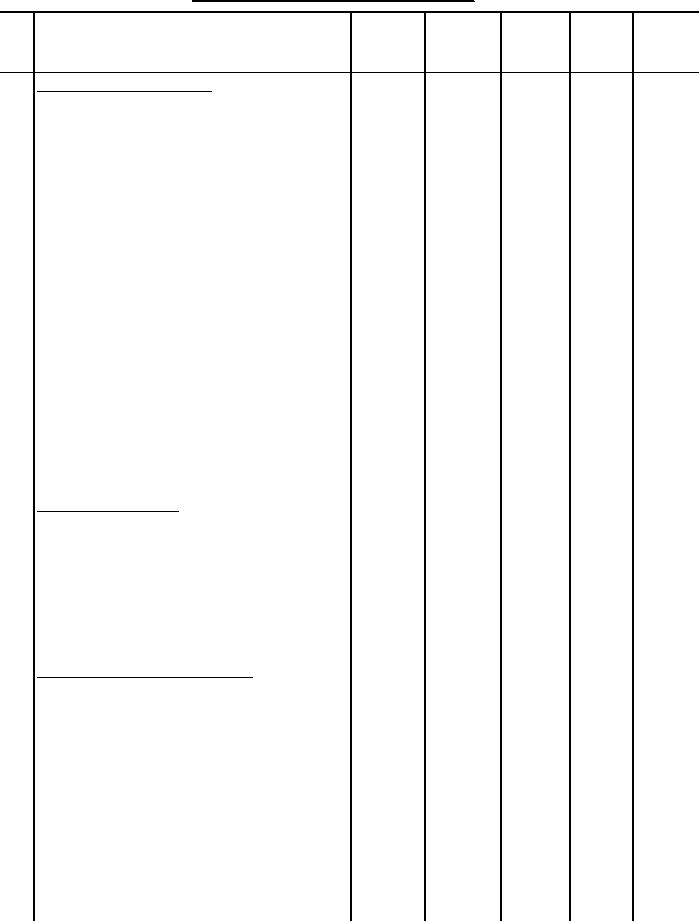

TABLE I.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

39 Join facing to fronts.

a. Position the left and right

fronts to the respective front facing

(face to face), with the notch of the

front in line with the notch on the

facing and with the front piped edge

approximately 3/8 inch from the front

edge of facing. Mark the facing

along the top, front and bottom edges

of jacket.

b. Lap the front edge of the right

301

LSa-1

10-14

A

A

and left fronts, respectively, on the

outside of the facing at the marks

and join the fronts to facing as

close as possible to, but not on top

of, the stitching joining the piping

to the front. The stitching shall

extend from the top to bottom edge of

jacket front edge only and the eyelet

cover shall be caught in the

stitching.

c. Trim excess facing material where

necessary.

40 Baste front edges.

a. Turn the facing-lining assemblies

to the inside of fronts, completely

working out the edges.

b. Baste along the front edge of

101

left and right fronts, working the

or

facing and eyelet cover back from the

Hand

folded edge of piping.

41 Baste facing (second time).

a. Baste the facing to the fronts

Hand

approximately 1-1/4 inches from the

or

top, front and bottom edges of the

301

Hopper

jacket, holding the lower corner of

the jacket in such a manner as to

cause the lower front edge of the

fronts to roll inward towards the

back edge of the facing.

b. Turn under and baste the top edge

Hand

of the facing even with the fronts

or

Hopper

from the collar notch to the front

301

edge, catching the turned under

portion of the facing in the basting.

29

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business