MIL-DTL-29478A(MC)

Manufacturing requirements - Continued.

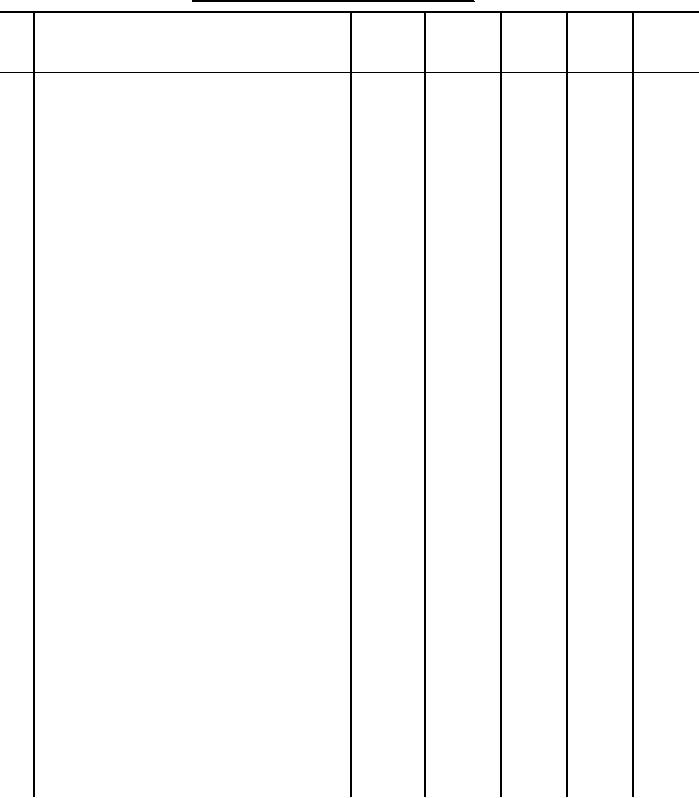

TABLE I.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

d. Position the collar on the vinyl

301

LSa-1

10-14

A

A

cord, with the upper edge of the

(silk)

(silk)

collar abutted against the cord edge.

Stitch collar to the vinyl cord 1/16

inch from edge of collar. Trim the

ends of the cord even with the ends

of the collar.

e. Position an eyelet cover on the

301

LSa-1

10-14

A

A

underside at each end of the collar,

(silk)

(silk)

with one edge of the cover 3/4 to 7/8

inch from the front end, and the

bottom raw edge of the eyelet cover

1/2 to 5/8 inch from the upper cord

edge. Stitch collar to cover along

the cord edge adjacent to the

stitching line of the collar.

f. Lap the upper cord edge of collar

301

SSa-1

10-14

A

A

(silk)

(silk)

over the top raw edge of collar

lining approximately 1/2 inch with

lining face up. Stitch collar to the

lining and eyelet cover along the

cord edge adjacent to the stitching

line of the collar. The stitching

shall extend from center to center of

the eyelet covers. The collar lining

shall extend approximately 1/2 inch

beyond the right end of the collar

and approximately 2-1/2 inches beyond

the left end of the collar for the

lining extension tab.

g. Turn collar lining and eyelet

cover at the seam to the inside of

collar and press smooth and flat with

a heated pressing iron or pressing

machine.

h. Attach metal eyelets through all

plies of the collar at each end

midway between the upper and lower

edges and 1-1/2 inches from the

finished ends. The eyelet covers

will not be caught in the eyelets.

21

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business