MIL-DTL-29478A(MC)

Manufacturing requirements - Continued.

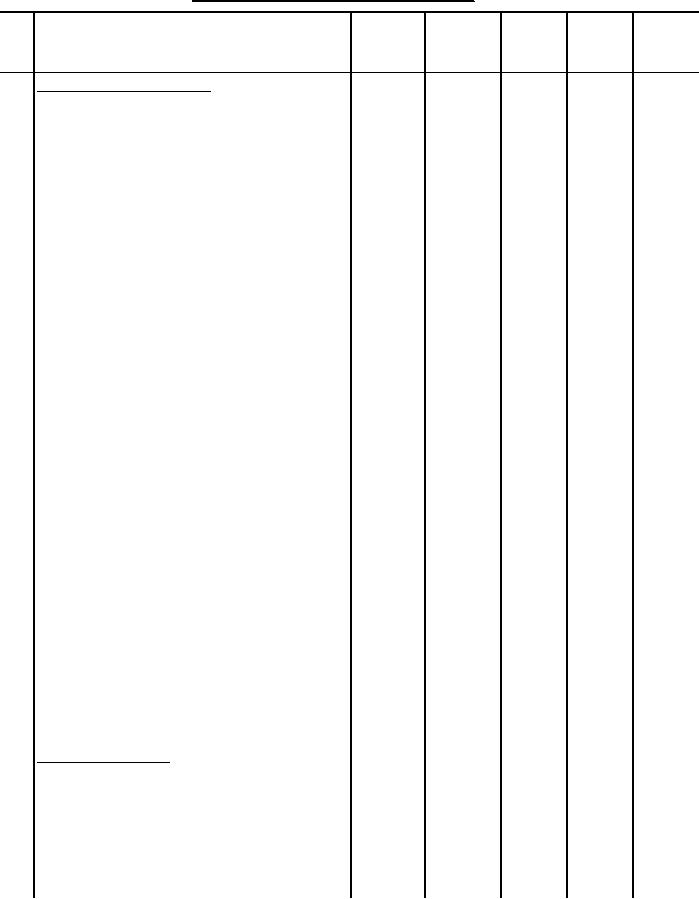

TABLE I.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

33 Stitch piping to coat.

Finished appearance. The piping

shall be uniformly stitched to the

coat without twists, puckers, or

pleats. The piping shall extend from

the collar notch at top edge of the

right front to the collar notch at

top edge of the left front.

a. Position the 1-1/4 inch wide

301

SSa-1

10-14

A

A

strip of piping material on the

outside of left and right front, with

one edge even with top, front and

bottom edges of coat. Stitch piping

to coat 1/8 inch from edge. The

piping shall extend from the collar

notch to the top, along the left and

right front and the bottom edge of

the coat.

b. Turn the piping to the inside

301

SSe-2

10-14

A

A

working out the folded edge of piping

(b)

(silk)

(silk)

1/8 inch beyond edges of coat.

Topstitch coat to the piping 3/16

inch from the folded edge of piping,

catching the turned under portion of

the piping in the stitching.

c. Notch out the excess piping

material at the top and bottom front

corners to eliminate bulkiness. Trim

the inner edge of piping on the right

front only from the upper front down

to approximately 1 to 1-1/2 inches

below the waist seam, so that the

piping will not interfere with front

buttonholes.

d. Overedge stitch the raw edge of

503

EFd-1

6-12

A

A

the piping at the bottom edge of

or

coat.

504

34 Interline fronts.

a. Position the left and right

301

Hopper

fronts on the respective coat front

or

interlining and baste the front to

Hand

the interlining from approximately

3-1/2 inches down from the shoulder

edge to approximately 2 inches up

from the bottom edge of the front.

27

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business