MIL-DTL-29478A(MC)

Manufacturing requirements - Continued.

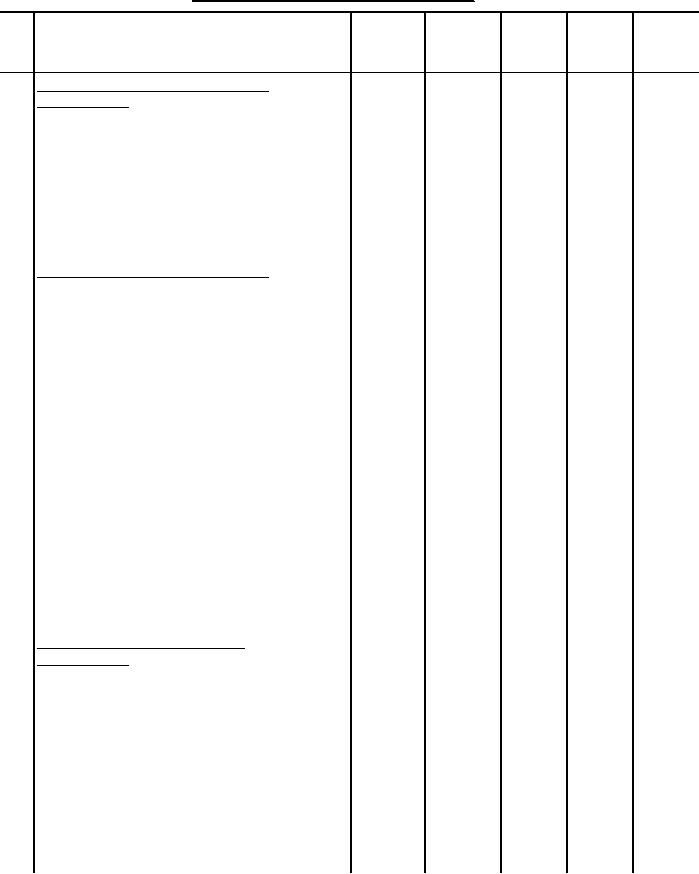

TABLE I.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

36 Bind front edge and gorge of

interlining.

a. Fold polyester and cotton back

301

EFa-3

8-10

A

A

over the top and front raw edge of

the interlining. Stitch along the

top and front edge with three rows of

stitches 1/4 inch apart, placing the

first row 1/8 inch from folded front

edge and catching the turned-under

portion in the stitching.

37 Bind top neck of interlining.

Finished appearance. The polyester

and cotton binding shall be uniformly

stitched along the gorge of the coat

front interlining from the collar

notch to the shoulder point.

a. Lap the 3/4 inch wide strip of

301

LSa-1

8-10

A

A

binding on the outside of the coat

front interlining from the collar

notch to shoulder point,

approximately 1/4 inch. Stitch the

binding to the interlining 1/8 inch

from the raw edge of the binding.

b. Smoothly fold the free edge of

301

SSa-1

10-14

A

A

the binding over the top edge and to

the underside of the interlining.

Secure the free edge of binding to

the interlining with a row of

stitches 1/8 inch from the raw edge

of the binding.

38 Fell piping to coat front

interlining.

a. Place the inner edge of piping on

101

the outside of the interlining at the

top, front and bottom edges. Baste

piping to interlining through the

fronts.

b. Fell the upper front and lower

301

EFc-1

4-6

A

C

edge of the piping to the coat front

or

(silk)

(silk)

interlining.

Hand

4-6

A

c. Pull and remove basting stitches

from piping.

29

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business