MIL-DTL-29478A(MC)

Manufacturing requirements - Continued.

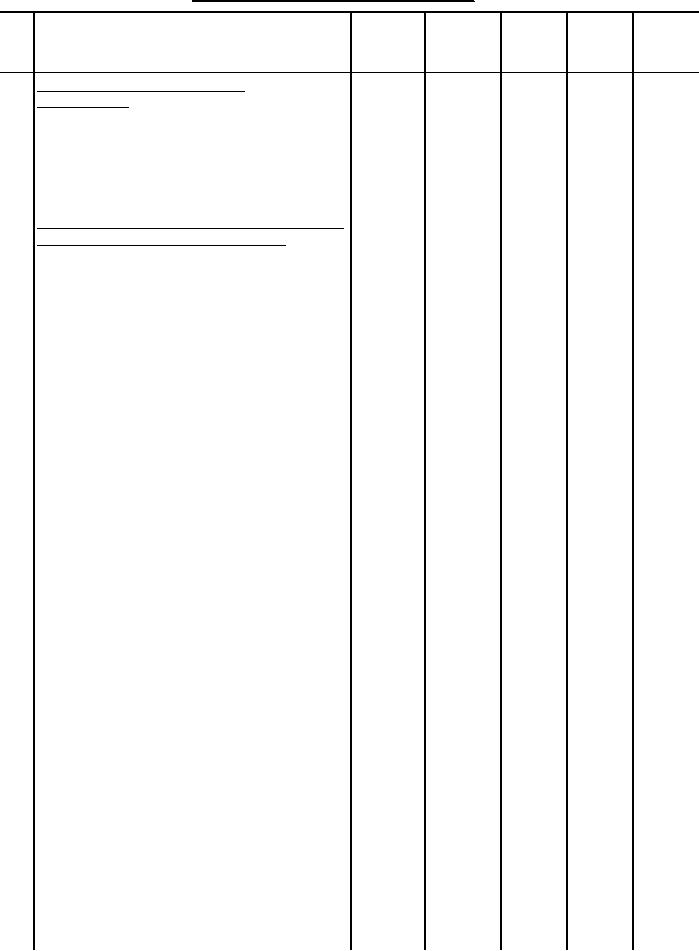

TABLE I.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

38 Fell piping to coat front

interlining. (cont'd)

d. Press the left and right fronts,

respectively, on a suitable type

heated pressing machine, with the

chest to conform to the shape of the

body.

39 Mark fronts for positioning the braid

and buttonholes (see Figure 4).

a. Mark the location of six

buttonholes on the outside of the

left front, as shown on Figure 4.

The top buttonhole (line A) shall be

positioned 1 inch below the upper

piped edge and 5/8 inch from the

front piped edge. The lower

buttonhole (line B) shall be on the

waist line and 5/8 inch from front

piped edge. The remaining four

buttonhole marks shall be evenly

spaced.

b. Extend each buttonhole line

towards the back and armhole edge

(line B shall be 1 inch shorter than

line A). The length of the top and

bottom line is determined by the

position of the harp on the second

line from the top which shall be

approximately 1-7/8 inches from the

armhole edge to the center of the

harp. The second line from the top

shall be measured from the front edge

of the buttonhole line to the center

of the harp. Transfer this

measurement to the bottom line less 1

inch. Draw a straight line from the

bottom line mark through center of

the harp up the top line,

establishing line A-C and B-D as

shown in Figure 4.

c. Bisect the top line A-C and

bottom line B-D and connect the

bisecting points with a straight line

E-F.

d. Position the right front of coat

on left front, collar notches even,

the right front edge 1 inch back of

the left front edge at collar notch,

and waist seam and armhole edge even.

30

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business