MIL-DTL-29478A(MC)

Manufacturing requirements - Continued.

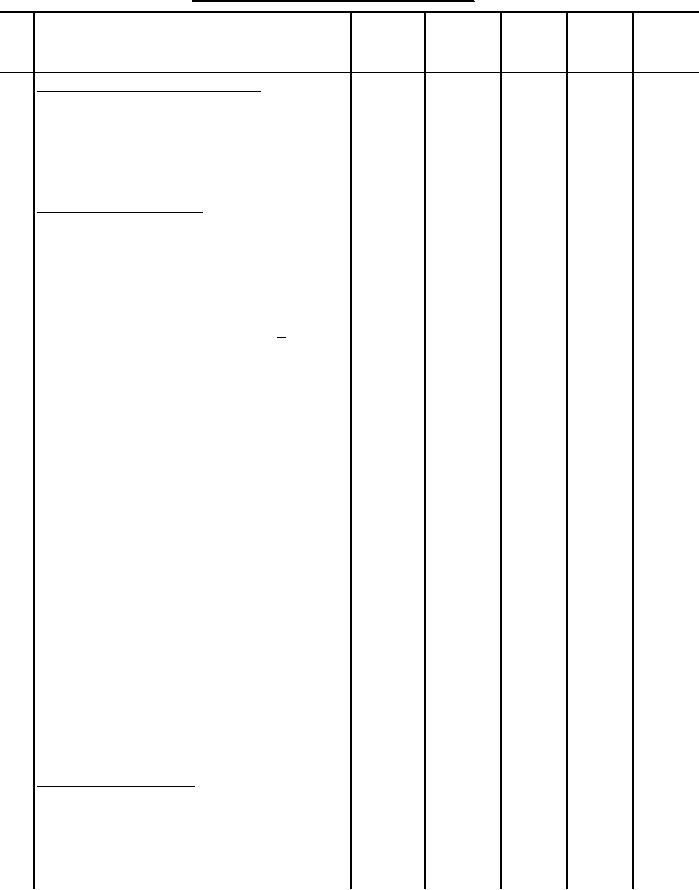

TABLE I.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

25 Sew on identification label.

(cont'd)

a. Sew the identification

301

SSa-1

10-14

A

A

instruction label to the outside of

(each

the left facing with a single row of

edge)

stitches 1/16 inch from each edge.

26 Pipe lower side back.

Finished appearance. The finished

piping shall be of uniform width,

without twists, puckers, pleats or

distortion. Piping shall extend

along the lower side back panel from

waist to bottom of coat for a

distance of approximately 12 + 3/8

inches.

a. Fold 1 inch piping in half

301

SSa-1

10-14

A

A

lengthwise. Seam piping 1/8 inch

from folded edge.

b. Overedge stitch the raw edges of

503

EFd-1

6-10

70

70

the piping together.

c. Mark along the back edge of the

side back for positioning the piping.

The mark line shall be 7/8 inch from

the back edge and shall extend from

the bottom of the side back to

approximately 12 inches above the

bottom head.

d. Position the folded edge of

301

SSa-1

10-14

A

A

piping on the mark and stitch the

piping to the side back panel 3/16 to

1/4 inch from the folded edge of

piping. Piping shall finish with a

minimum of 1/2 inch excess at top end

to give a neat appearance. In the

finished coat, the folded edge of

piping shall extend 1/8 inch beyond

the seam.

27 Make front and back.

Finished appearance. All joining

seams shall finish smooth and flat

without pleats, puckers, or gathers.

The seams shall start and finish

evenly.

24

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business