MIL-DTL-29478A(MC)

Manufacturing requirements - Continued.

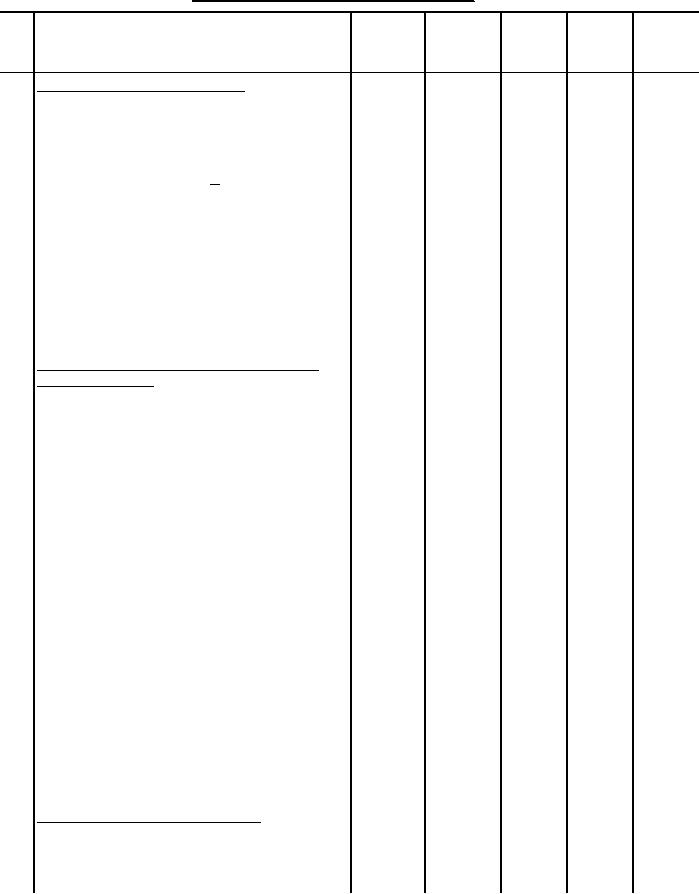

TABLE I.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

50 Hem bottom edge of lining.

Finished appearance. The hem shall

be uniformly stitched and shall

finish smooth and flat without

twists, gathers, puckers, or pleats.

The hem shall be 3/4 + 1/8 inch wide.

The lining securing straps shall be

positioned on the back in line with

back seam of coat.

a. Hem the bottom edge of body

301

EFb-1

10-14

A

A

lining with the raw edge turned under

and with one end of the securing

straps positioned and caught in the

stitching 1/16 inch from the upper

folded edge of hem.

51 Tack the lining securing straps to

bottom of coat.

Finished appearance. The lining

securing straps when tacked to the

bottom edge of coat shall not cause

twists or other distortions to either

the coat or the lining. The end of

the securing straps shall finish

between the piping at bottom edge of

coat and the skirt seam allowance.

In the finished coat, the lining

shall not be visible below the bottom

edge of the coat.

a. Position and securely tack the

301

SSa-1

10-14

A

A

free end of the securing straps to

the piping at the bottom edge of coat

through the skirt seam allowance.

b. Position the bottom edge of the

301

OSf-1

10-14

A

A

lining so that in the finished coat,

the lining shall not be visible below

the bottom of coat. Fold the lining

securing straps across the width and

stitch approximately 1/4 inch from

the folded end in order to hold the

lining in position.

52 Trim lining and interlining.

a. Trim the excess coat front

interlining and front lining at the

armhole.

36

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business