MIL-DTL-29478A(MC)

Manufacturing requirements - Continued.

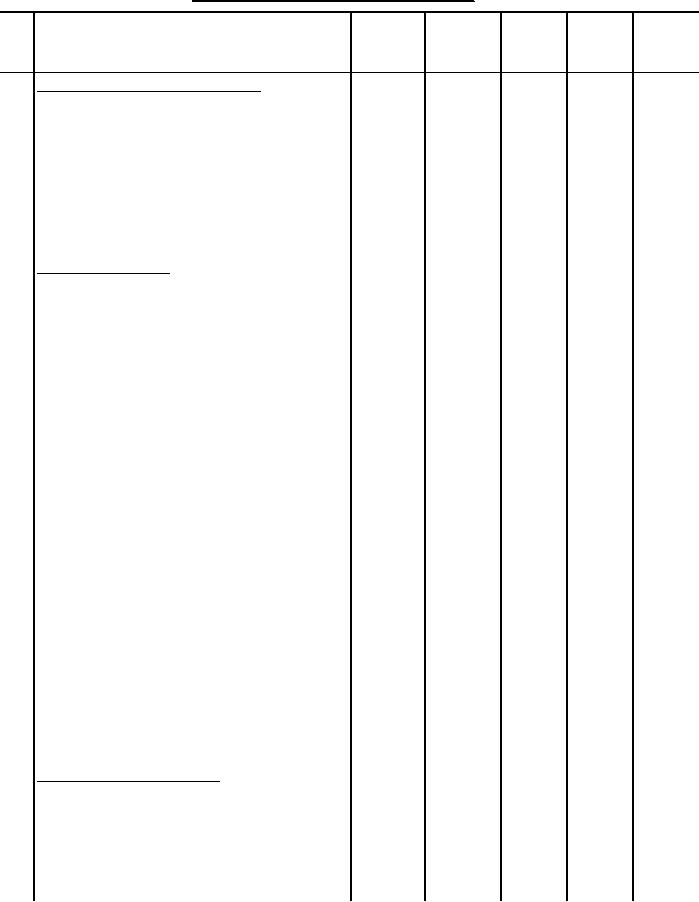

TABLE I.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

52 Trim lining and interlining.

(cont'd)

b. Trim the back lining even with

the neck.

c. Trim the shoulder edge of the

front and back lining to

approximately 3/4 inch from shoulder

at the armhole edge and taper the

trimming to 3/8 inch at the neck.

53 Make buttonholes.

Finished appearance. The buttonholes

shall be clean-cut, well made, well

worked over gimp to fit 40-line

insignia buttons. The gimp and

thread shall be pulled through to the

outside of the front. The purling of

the buttonholes shall be on the

facing side. The inside edge of the

eyelet end of the buttonhole shall be

5/8 inch from the front edge of coat.

The buttonholes shall be cut first

type.

a. Remove the basting on the

unstitched portion of the braid.

b. Make a horizontal eyelet end,

Button-

60 per

B

F

square-bar type buttonhole cut 1-1/4

hole

button- (silk)

(silk)

inches long at each of the marks.

hole

c. Securely bartack the end of each

Bartack

21 per

A

A

buttonhole, catching the ends of the

bartack (silk)

(silk)

gimp and thread in the bartack. Trim

the ends of the gimp and thread.

d. Rebaste the unstitched portion of

the braid around the buttonholes and

complete that portion of the

stitching through all plies (see

Figure 5).

54 Make eyelets in fronts.

Finished appearance. The eyelets

shall be worked with the purling on

the outside of the coat, and shall

finish with a 1/8 inch diameter

opening.

All stitches shall be

securely caught in the fabric.

37

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business