MIL-DTL-29478A(MC)

Manufacturing requirements - Continued.

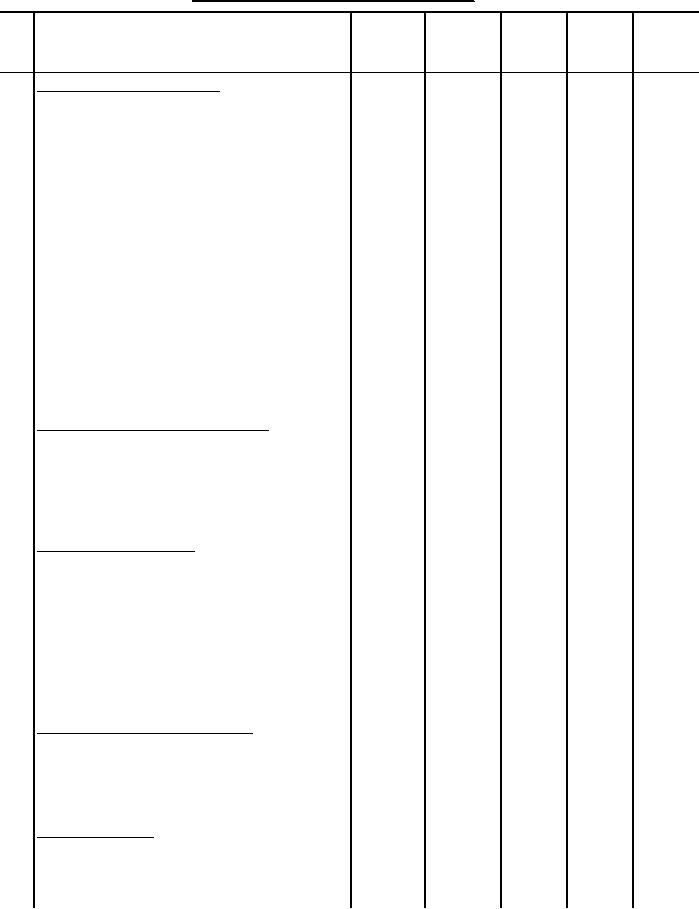

TABLE I.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

54 Make eyelets in fronts.

(cont'd)

a. Mark the right front for the

location of six eyelets for removable

insignia buttons to align with the

buttonhole on the left front. The

mark for the top eyelet shall be in

line with the right end of collar and

the remaining eyelets shall be in

vertical alignment with the top mark.

b. Mark location for eyelets on the

right and left front for removable

buttons. The mark for the eyelet

shall be between the braid strands at

the top end of each harp.

c. Make an eyelet at each of the

Eyelet

22 per

A

A

marks through all plies. The eyelet

eyelet

cover on the right front shall not be

caught in the stitching.

55 Make button openings in back.

a. Cut a 1/4 inch vertical opening

at the intersection of the side and

waist seams on the back. The ends of

the openings shall be hand or machine

tacked.

56 Press front of coat.

Finished appearance. Fronts shall be

finished smooth and flat without

distortion, with all edges uniformly

worked out.

a. Press the front of coat and braid

smooth and flat with a suitable

pressing machine, removing the

fullness.

57 Baste shoulder pad to coat.

a. Insert shoulder pads between

Hand

interlining and chest padding of coat

or

fronts. Securely tack the pad to the

301

Hopper

interlining and chest padding only.

58 Seam shoulders.

Finished appearance. The shoulder

seam shall finish without a distorted

appearance.

38

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business