MIL-DTL-29396B(MC)

Manufacturing requirements - Continued.

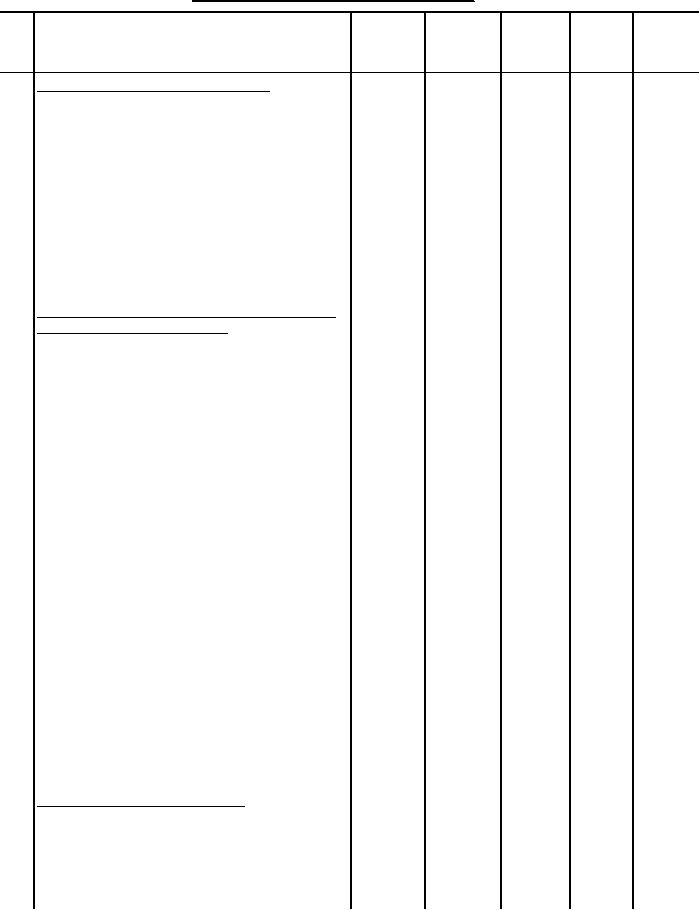

TABLE I.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

28 Join back and front at sides.

a. Position the side back and side

301

SSa-1

10-14

A

A

fronts face to face with edges even,

and join together at the side with

3/4 inch seam.

b. Spread open side and back seams

and press smooth and flat with a

heated pressing iron.

c. Mark and shape the bottom of

front and back in accordance with the

pattern shaper.

29 Seam reinforcement stay to shoulder,

armhole, gorge and neck.

Finished appearance. The

reinforcement stays shall be sewn to

the armhole and shoulder edge of the

front without gathers, puckers or

pleats. The top end of the armhole

stay and lower end of the shoulder

stay shall form a right angle at the

armhole without the stays overlapping

each other.

a. Seam the 3/4 inch wide stays to

301

SSaa-1

10-14

A

A

the underside of the front along the

shoulder edges and upper front edge

of the armhole, respectively, 1/8

inch from the outer edges. The strip

for the shoulders shall be positioned

approximately 1/2 inch from neck and

armholes respectively. The strip for

the upper edge of armholes shall be

positioned approximately 1/2 inch

from the shoulder. The strip for the

gorge shall be positioned

approximately 1/2 inch from shoulder

seams across center back. The strip

for the neck shall be positioned 1/2

inch from shoulder seams to 1/2 inch

from front collar notches.

30 Mark and dress left front.

a. Mark and dress the left front

edge of jacket, from the top notch to

the bottom notch. The mark line

shall be 1 inch from the upper front

edge to the bottom front edge.

24

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business