MIL-DTL-29396B(MC)

Manufacturing requirements - Continued.

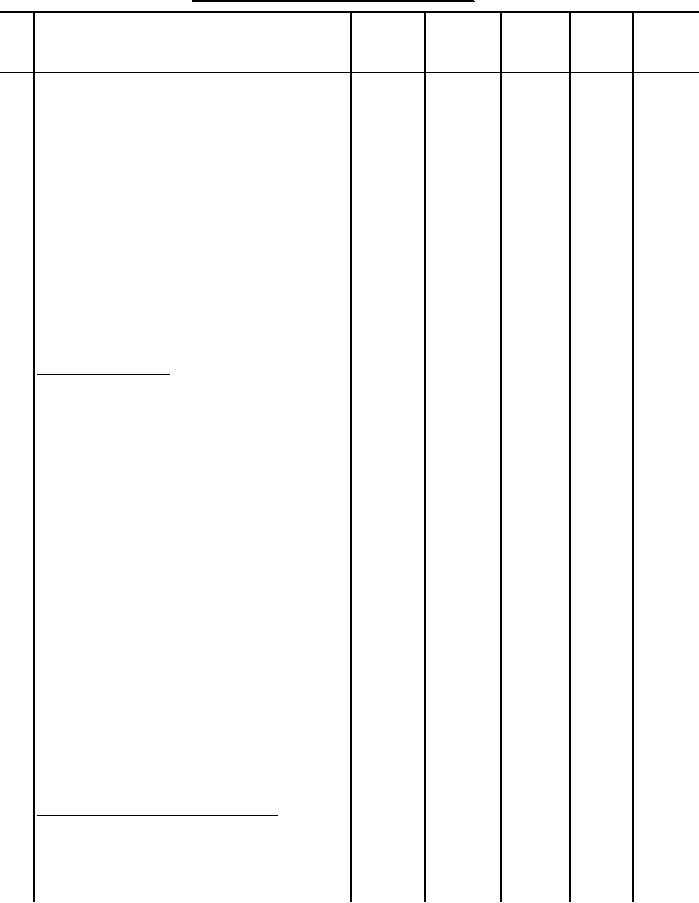

TABLE I.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

b. Turn the piping to the inside,

301

SSe-2

10-14

A

A

working out the folded edge of piping

(b)

1/8 inch beyond edges of jacket.

Topstitch jacket to the piping 3/16

inch from the folded edge of piping,

catching the turned under portion of

the piping in the stitching.

c. Notch out the excess piping

material at the top and bottom front

corners to eliminate bulkiness. Trim

the inner edge of piping on the left

front only from the upper front down

to approximately 1 to 1-1/2 inches

from bottom edge of front, so that

the piping will not interfere with

front buttonholes.

34 Interline fronts.

a. Position the left and right

301

Hopper

fronts on the respective jacket front

or

interlining and baste the front to

Hand

the interlining from approximately

3-1/2 inches down from the shoulder

edge to approximately 2 inches from

the bottom edge of the front.

b. Baste along the shoulder,

301

Hopper

allowing room for setting the

or

shoulder pad and working the fullness

Hand

toward the armhole. Baste along the

front of the armhole approximately

1-1/2 inches from the edge and

continue to baste down the back edge

of interlining, across the waist

dart, to approximately 2 inches from

the bottom edge of fronts. Baste

along the top edge from the basting

stitches for the shoulders to

approximately 1-1/2 inches from the

front edge. Continue to baste

approximately 1-1/2 inches from the

front edge to the bottom edge of

fronts.

35 Trim jacket front interlining.

a. Trim the top edge of jacket

interlining even with the top edge of

fronts from the point of shoulder to

the collar notch.

26

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business